Carrier 06E User Manual

Browse online or download User Manual for Conditioners Carrier 06E. Carrier 06E User Manual

- Page / 16

- Table of contents

- BOOKMARKS

- Hermetic, Water-Cooled 1

- " 2Va ”■ 2

- ELECTRICAL REQUIREMENTS 3

- ACCESSORIES 3

- REFRIGERANT CHARGING 4

- INITIAL START-UP 4

- 40 SEC +5 5

- 150 SEC 5

- UNLOADED OPERATION 6

- LOADED OPERATION 6

- X 5/8 in 8

- X 1/2 in 8

- 53) \ ' V 9

- VALVE PLATE 11

- SUCTION VALVE ? 11

- (VALVE PLATE) 11

- SUCTION VALVES < 11

- ■r--7.7X 12

- 13

- . 'Cv • 14

- (Clean-Up Procedure) 15

- MOTOR BURNOUT 15

Summary of Contents

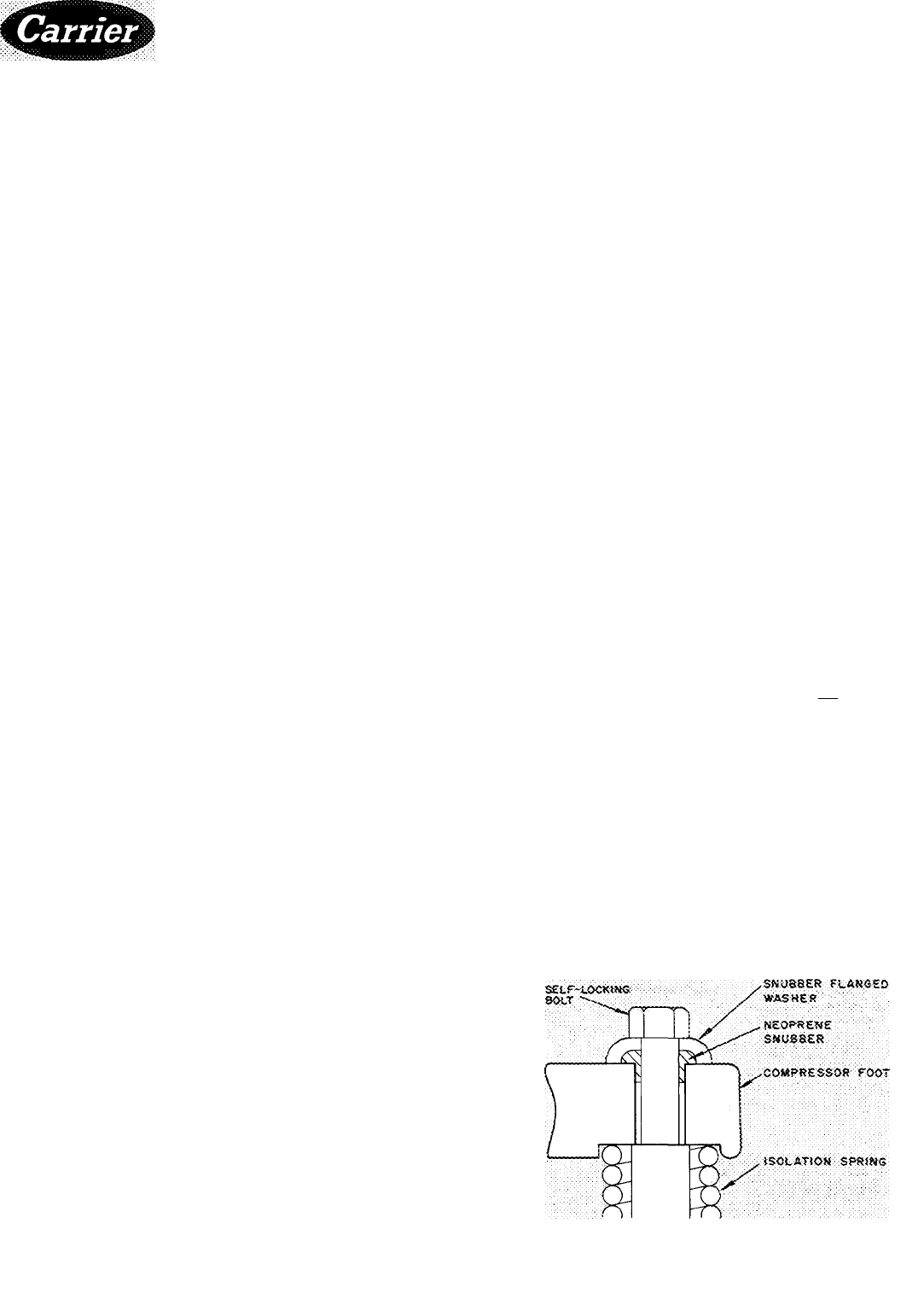

Compressors and Condensing UnitsHermetic, Water-CooledPRELIMINARY CHECKSInspect shipment for damage. File claim with the shipping company if

Table 4 — Torque ValuesSIZEDIAM(in.)THREADS PER IN.TORQUERANGE(Ib-ft)USAGEXe27 (pipe)8-12Pipe Plug — Crankshaft%1820-25 Pipe Plug — Crankcase%208-108-

2. Place the pump vanes, pump vane spring with guides, and snap rings into the bearing head. Compress the springs and force the s

2. Push terminal bolt thru terminal plate and remove insulating washers.Inspect for grounds, insulation breakdown, and sufficient life r

Stator is a slip fit in motor housing. It is held in place by both an axial key and a locking assembly consisting of an acorn

REMOVE1. Acorn nut and washer.2. Back out locking pin and bushing.REPLACE1. Screw in locking pin bushing until it rests on stator core.2.

MOTOR BURNOUT (Clean-Up Procedure)When a hermetic motor bums out, the stator winding decomposes forming carbon, water and acid which con

#Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurri

M ODF*DISCHARGE VALVE (MAY BE ROTATED 180°DIAM KNOCKOUTL ODFSUCTION VALVE (MAY BE ROTATED 360° AT 90° INTERVALS)2-31| OVERALL HEIGHT'A~ OVERALL L

Table 2 — Electrical Data (60-Hertz, 3-Phase) (Circuit Breakers Selected for Units Using R-22)VOLTSNomina 1200230Supply Range180-229207-264MÀXMAXUNITK

REFRIGERANT CHARGING Evacuate, Dehydrate and Leak Test the entire refrigerant system by methods described in Carrier Standard Service T

Timer Functions (See Fig. 5 — Tinier Cycle)1. Switch A (contacts A-Al and A-A2) provides Time Guard® function. Start of compressor is del

PRESSURE DIFFERENTIAL ADJUSTMENT SCREWSEALING BYPASS CYLINDERCAP PISTON HEADCONTROL SET POINT ADJ NUTPOPPET VALVE'BLEED ORIFICE'DISCHA

Capacity Control Valve Operation (Fig. 6)LOADED - When suction pressure is above control point, the poppet valve closes. Discharge gas

Fig. 10 — Gravity CirculationceOTarcGAt. pcwp sas vemt-30 OPM AT 35' HEADPRl«WS /VAl.VE£\.. PUMP. • " ^SUCT:ON: ClXSt VENT PIPE ; VALVE WH

V-_________... ^53) \ ' V.^ ^(SEE LEGEND PAGE 8)Fig. 12 — 06E Compressor Components

(38 pages)

(38 pages)

Comments to this Manuals