Carrier 48DD User Manual Page 3

- Page / 6

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

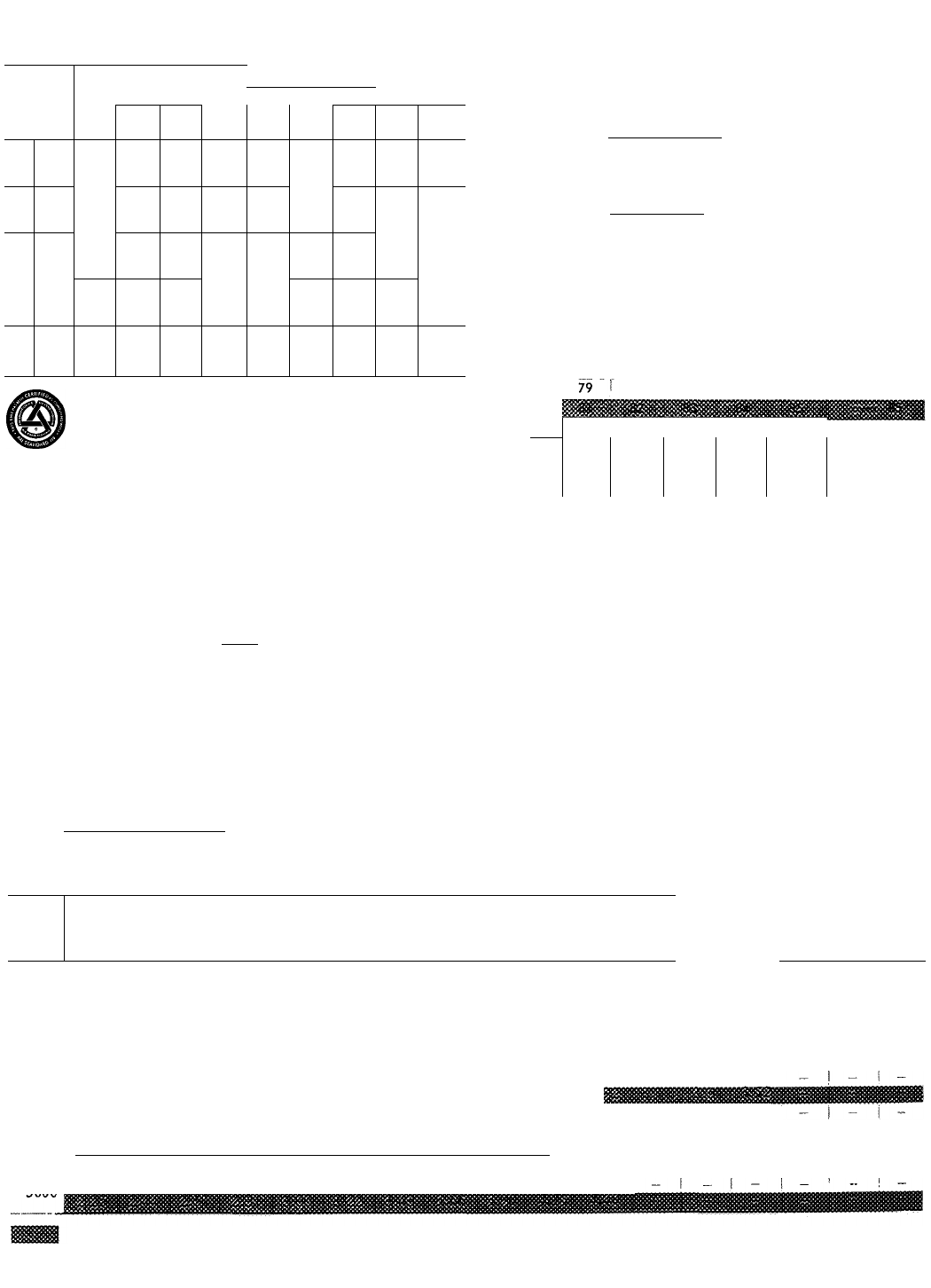

PERFORMANCE DATA

COOLING CAPACITIES (60-Hz)

48DD012 ARI* - 124,000 BTUH

T emp (F)

Air Ent

Cond

Evap A

3000/.08” I ’ 4"c

ir — Cfm/B F

)6o/. 1 2

00/.10 1 5C

72 *62

lygp A

12

ir - E

ei

wkiF

62

67 62

TC 147 1

134 8 122 5

149 4 139.4

129 5

153 0

144 1

131 0

85

SHC

73 0 87 5 103 5

78 8 99 6 120 2

87 7 1115 131 0

KW 14.4

14.C

13.4

14.7

14.2 13.9 14,7 14.6

14.2

TC

138 9

128 i

117 4 141 6

132 2 123 8

146 2 136 8

128 6

95

SHC

68 7

84.9 101 4

76 3

96 4 117 6

83 4

108 2

128 6

KW 15.6 14.9

14.2

15.9 15.2 14.6

16.3 15.6 15,0

TC

134 0 124 S 114 8 137 6

128 2

117 3

142 6 133 4 125 1

100 SHC

67 3

84 0 99 6 73 7

94 9

114 8

82 2 107 0 125 1

KW

16.1

15,3 14.6 16,3 15,7

15.5 16.5 16,0

15.4

TC

130 4 120 7

ms 133

123 8

114 8 147 2 128 9

"l21 7

105

SHC 65 3 81 6

98 2

71 8 92 9 89 7

79 9

105 0 121 3

KW 16.7 15,8 15.0 16.9 16. 1

16.9

17.1 16.6

15.9

TC 121 0 112 1 104 1 123 6

114 8

109 1 126 9

117 0 114.0

115

SHC

61 .6

78 4

96 8

68 3

89 7

109 1 75.9

101 5

1 14 0

KW 17.6

16.6 15 6

17.7 16.9

16 2

18 3

17 3

16 8

*Rated in accordance with latest ARI Standard 210

Capacities shown (except ARI) are gross capacities

which do not include a deduction for indoor fan

motor heat.

BF — Bypass Factor

Ewb — Entering Wet-Bulb

KW — Compressor Motor Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh)

NOTES:

1. Direct interpolation is permissible Do not extrapolate

2 The following formulas may be used:

sensible capacity (Btuh)

1 08 X cfm

f|wb ^ Wet-bulb temperature corresponding to enthalpy of air

leaving evaporator coil (h|y^,[з)

total capacity (Btuh)

4.5 X cfm

Where

hewb^ Enthalpy of air entering evaporator coil

SHC is based on 80 F edb temp of air entering evaporator coil

Below 80 F edb, subtract (corr factor x cfm) from SHC

Mdb fedb ■

h|wb - ■

BF

Entering Air Dry-Bulb Temp (F)

78 I 77 1 76 I 75 [ under 75^"

Correction Factor

10

97 1 95

2 92 3 89

4 86

20

86 1 73

2 59

3 46 4 32

.30 76

1 51 2 27 3 03 3 78

use formula

shown below

Interpolation is permissible

Correction Factor = 1.08 x (1 - BF) X (edb - 80)

UNIT 48DD012

First Stage

Full

INPUT

(Btuh)

37,000

275,000

BONNET

(Btuh)

103.000

206.000

HEATING CAPACITIES

3 At altitudes above 2,000 ft, the following formula may be used:

bonnet capacity

NOTES

1 Ratings are approved for altitudes to 2,000 ft At altitudes over

2,000 ft, ratings are 4 percent less for each 1,000 ft above sea

level

2 At altitudes up to 2,000 ft, the following formula may be used

to calculate air temp rise:

At

----

--------------------

( 24 X specific weight of air x 60) (air quantity)

4 Maximum allowable gas pressure is 14 0 in wg Minimum

allowable gas pressure for full rated input is 5 0 in wg

5 Unit may be field converted for 100 percent LP gas, using

Carrier factory parts Units will maintain A.G A, certification if

conversion is performed as directed and conversion nameplate is

attached to unit adjacent to existing unit nameplate

At =

bonnet capacity

1.08 X air quantity

FAN PERFORMANCE, 48DD012

CFM

EXTERNAL STATIC PRESSURE (in. wg)

.4 r .5 [ .6 [ .7 1 .8 ] .9 j 1.0 ^ 1.1 1 1.2

1 I

1.5 1 1.6

I

Fan Rpm

3000

3400

- I

! 1020 I 1080 I 1140 I 1210 \ 1265 1 1325 I 1380 I 1430 I 1475 i 1520 T (560 I 160? I 1650 1 1695 I

J

3800

970 <1030 <1095 \ 1155 1(215 I 1270 I 1320 ! 1380 ! 1425 I 1470 ¡1515 I (560 I (605 i (6.50 i (695

4000

! 1010 i 1075 i 1135 < 1195 i 1245 I 1300 ¡1355 1 1405 I 1450 I 1495 ¡1540 I 1590 i (655 1 1680 I

4200

( 1055 < 1115 ! ((75 I 1230 : 1275 i 1330 i 1385 : 1430 i 1480 i 1520 5 (565 i (6(0 , 1655 \ 1700

4600

1145 ! (200 I 1245 I 1290 I 1345 ! 1400 i 1445 I 1485 I 1530 ! 1575 \ 1620 \ 1665 I

“i 1230 j 1270 I 1315 I 1370 1 1420 i 146.5 > 1510 ' (5.50 i 1595 <1640 <1685 \

Motor brake horsepower

NOTES:

1 Fan performance has deductions for unit casing losses, wet coil,

heat exchanger, and clean filters

2. Fan motor bhp is based on minimum voltage and 80 F air

across the standard motor

3. All table values printed in italics indicate non standard conditions

(18 pages)

(18 pages)

Comments to this Manuals