Carrier 38CQ User Manual

Browse online or download User Manual for Conditioners Carrier 38CQ. Carrier 38CQ User Manual

- Page / 20

- Table of contents

- BOOKMARKS

- Heat Pump - Outdoor Section 1

- MOUIMTirJtTP^ 2

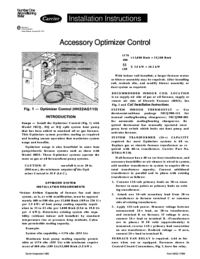

- Fig. 5 — Accessory Coupler 4

- ELECTRICAL DATA AND WIRING 4

- ODT — Outdoor Thermostat 5

- _________ 6

- A ccuRater*^^ 7

- Table 7 — Compressor Data 14

- Fig. 31 — Component Location 14

- 20 + 5 5+3 15

- Compatible Fitting Repair 16

- FAN BLADE 17

- "" 17

- X 0.4732 20

- X 0.7457 = kW 20

Summary of Contents

Carrier Parkway • Syracuse, N Y 13221Heat Pump - Outdoor Section4'0" OVERHEAD SPACE REQ'D FOR SERVICE AND AIRFLOWLIQUID LINE CONN LI

Fig. 17 — 38CQ033 with 40AQ030 Cooling Cycle Charging Chart (R-22)360340S» 320 £^ 300-o 280 o260-240-220200DRY-BULB TEMP AIR ENT OUTDOOR UNIT(F)WET

Fig. 21 - 38CQ039 with 40AQ036 or 40FS160/ 28MQ036 Cooling Cycle Charging Chart (R-22)PRESSURE AT SUCTION SERVICE VALVE (PSIG)Fig. 23 - 38CQ039

PRESSURE AT SUCTION SERVICE VALVE (PSI6)Fig. 25 - 38CQ044 with 40FS160/28MQ042 Cooling Cycle Charging Chart (R-22)PRESSURE AT SUCTION SERVICE VALVE (P

Fig. 29 - 38CQ048 with 40FS200/28MQ048 Cooling Cycle Charging Chart (R-22)300280260>240fE 220£ 180140120WET-BULB TEMP AIR ENTOUTDOOR UNIT{F)9F-I0.

Compressor Removal — See Table 7 for compressor information and Fig. 31 for component location. Follow safety codes, and wear safety glass

Unit Controls and Safety DevicesHIGH-PRESSURE RELIEF VALVE is located in compressor. Relief valve opens at a pressure differential of approxim

ACCESSORY FILTER DRIERSUCTION SERVICE PORTAT SERVICE VALVE (HTG CYCLE)OUTDOOR COILSUCTION SERVICE PORTLIQUID LINE SERVICE PORT AT SERVICE VALVE (CL6 C

Outdoor Fan Position — Required fan position isshown in Fig. 35. Adjust fan by loosening setscrewand moving fan blades up or down.Fan Motor Removal1.

TROUBLESHOOTING CHART - COOLING CYCLE00

TROUBLESHOOTING CHART - HEATING CYCLE

MOUIMTirJtTP^Step 4 — On the Ground: Mount Unit on a Solid, Level Concrete Pad. See Fig. 2 for pad dimensions. Position unit so that coil dr

SI METRIC CONVERSIONS(°F - 32) X 5/9= °CBTU X 1.055 = kJBTU/hr X0.2931 = WTons refrig x 3.517= kWHP X 0.7457 = kWkcal/hr X1.163= Wft X0.3048= mft^x 0.

Table 3 — AccessoriesPART NO.DESCRIPTION38CQ90008138C 0900111Low-Voltage Control — Honeywell Thermostat HH07AT071 and Thermostat Subbase HH93AZ073 — (

factory supplied with a No. 8 AccuRater piston for installation in 28MQ048. For piston replacement instructions, see AccuRater’’"'&

fTHERMOSTAT SUBBASE HH93AZ073 OR HH93AZ07540AQ FAN COIL COOLING CONTROL KIT TERMINAL BOARD38CQTERMINALBOARDTHERMOSTATSUBBASEHH93AZ0730RHH93AZ07540AQ O

3-PHASE CONN. TO FUSED DISCONNECT_________BLK-I-PHASE CONN. TO FUSEDDISCONNECTBLK-YEL OR BLK------L ------------GROUND LUG38CQ HEAT PUMP CONTROL BOXFi

(OD (liquid line), respectively, using refrigerant weights shown in table below. (Twenty-five feet of 3/8-in. OD tubing contains 14.4

COOLING CYCLE CHARGING CHARTMETHOD1. Operate unit a minimum of 10 minutes before checking charge, and after each charge adjustment.2. Me

PRESSURE AT SUCTION SERVICE VALVE (PSI6)Fig. 13 — 38CQ027 with 40AQ024 Cooling Cycle Charging Chart (R-22)Fig. 15 — 38CCX)27 with 40AQ030 Cooling Cycl

More documents for Conditioners Carrier 38CQ

(12 pages)

(12 pages) (8 pages)

(8 pages)

Comments to this Manuals