Number One

AirConditbning

Maker

Carrier Parkway • Syracuse, N Y 13201

Single-Package Cooling Units

INSTALLATION

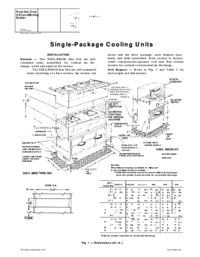

Unit Support — Refer to Fig. 1 and Table 1 for

unit weight and dimensions. Construct a stand or

frame of I-beams or angle iron that supports unit

weight and size if desired. The floors and floor

joists of existing buildings may require reinforce

ment. Follow applicable codes.

Rigging and Unit Placement — Inspect unit for

shipping damage. File any claims with trans

portation agency. Provide space around unit for

service, fdter access and overhead plenum clearance

(Fig. 1). Use rollers under shipping rails. Unit may

be moved by hand truck on any side. Do not

remove shipping rails until unit is at final location.

Unit Isolation — If desired, install isolators be

tween floor and base of unit.

Installing Accessory Plenum — Holes in unit top

panel match holes in plenum. Use screws provided

(shipped in cloth bag taped inside plenum) to

attach accessory plenum to top of unit. See Fig. 1

and 2.

Installing Heating Coil — Water and steam heating

coils must be installed thru the back of the unit

as described in Installation Instructions shipped

with accessory coil.

Supply Air (Evaporator) Ductwork — Connect

ducts to flanges on air supply opening (Fig. 1) with

a flexible connection. Attach ductwork to building

structure and insulate with fiber glass and vapor

barrier to prevent sound transmission and

condensation.

Alternate Return Air Opening — Unit back panel is

stamped to indicate alternate return air (or out

door air inlet) opening as shown in Fig. 1.

1. Cut out alternate return air opening as required.

Table 1 — Physical Data

UNIT 50BA004

SOB B 004

50BA006

50BB006

OPERATING WT (lb)

390

330 427

360

Accessory Plenum

25 (approx)

COMPRESSOR No. ... Type

1 . M34

1 M34 1 R542

1 R702

Cy! inders

2

2 3

4

Oil Capacity (pts)

3

3

5 5

Crankcase Heater

No

Yes No Yes

REFRIGERANT, TYPE 22 Full

Holding

Full Holding

Operating Charge (lb) 3 5 + 25

-

4 6 + 25

-

INDOOR AIR FAN, Type

Nominal Cfm

Motor Hp ... Frame (NEMA)

Motor Pulley Pitch Diameter

Fan Pulley Pitch Diameter

Belt No. ... Size

Fan Speed Range (Rpm)

Max Allowable Fan Speed (Rpm)

Speed Change per 1/2 turn of

movable motor pulley flange (Rpm)

Movable Pulley — Max full turns

from closed position

Factory Setting (full turns open)

INDOOR AIR FILTERS,

Size (in.)

No.

_______

_

______

__

PRESSURE SWITCHES

High (P='9)

Cut-in (psig)

Low

Type

Cutout (psig)

Cut-in (psig)

Adjustable, Belt-Driven Centrifugal

1200

1200

2000

2000

Std

/3 ... 48

‘/3 ... 48

14 ... 56

% ... 56

Alt

% ... 56

Y4 ... 56

1 ... 56 1 ... 56

Std

1.9 to 2 9

1.9 to 2.9

2 4 to 3 4

2.4 to 3 4

Alt

2.4 to 3 4

2 4 to 3.4 3.4 to 4 4

3 4 to 4 4

6 4

6 4 6 4 6.4

1 . 4L480

1 4L480 1 4L480 1 . 4L480

Std

512 to 782

512 to 782

647 to 915 647 to 9 15

Alt

647 to 915

647 to 915

9 16 to 1186 916 to 1 186

1100

1100 1100 1100

Std

27 0

27 0

26.8 26.8

Alt

26 8

26 8

27.0

27 0

5

5

5

5

3V2

3V.

4

4

1-in. Throwaway

16 X 25

16 X 25

16 X 25

16 X 25

2

2

2

2

428 ^ ^

-

428 „

-

320 + 20

-

320 + 20

-

_

27 + 4

27 + 4

-

-

60 to 78

60 to 78

NOTES: 1 Fan motor with 48 frame has 1/2-i

motor cannot be used on 48 frame

2. Water-cooled condenser maximum

n diam shaft: 56 frame, 5/8-in shaft. 56 frame

motor mounting bracket,

working pressure on water side is 450 psig

© Carrier Corporation 1977

Form 50BA,BB-5SI

(8 pages)

(8 pages) (8 pages)

(8 pages)

Comments to this Manuals