Carrier AQUAZONE 50RHC006-060 User Manual Page 34

- Page / 44

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

34

Aquazone™ water source heat pumps are available in a

flexible, efficient array of models, which can be used in all

types of water loop, ground water, and ground loop type

systems. Aquazone products provide optimal energy

efficient solutions and adapt to the most challenging design

requirements.

AQUAZONE PRODUCT GUIDE

Water loop system

Water loop (or boiler/tower) system applications typically

include a number of units plumbed to a common piping

system. For optimal performance, this system should be

designed between 2.25 and 3 gpm per ton of cooling ca-

pacity. The system is comprised of highly efficient pack-

aged reverse cycle heat pump units interconnected by a

water loop. The water circuit serves as both a sink and

source for heat absorption and rejection and is designed

for entering water temperatures between 60 F and 90 F.

Within this temperature range units can heat or cool as re-

quired from the same water source. Transferring heat from

warm to cold spaces in the building, whenever they coex-

ist, conserves energy rather than creating new heat.

Refer to the Carrier Water Source Heat Pump Sys-

tem Design Guide for assistance designing water loop

systems. The guide includes a practical approach for the

most current design recommendations including:

• Product application including horizontal, vertical, con-

sole, rooftop and water-to-water applications.

• Ventilation methods and system design including energy

recovery.

• Acoustical considerations for different product types.

• Addressing IAQ issues such as condensate removal,

humidity control.

• Air Distribution Design including diffuser selection/

layout and ductwork design.

• Hydronic System Design including pipe sizing/layout

and boiler/tower sizing.

• Control Configurations such as stand alone, DDC,

DCV, and VVT®.

• WSHP Efficiency/Operational Cost Comparison chart.

• System variations such as a system without a boiler,

variable pumping, and VAV for interior use.

Condensate drainage

Ven ting — Properly vent condensate lines to prevent fan

pressure from causing water to hang up in the piping.

Condensate lines should be pitched to assure full drainage

of condensate under all load conditions. Use chemical

treatment to remove algae in the condensate pans and

drains in geographical areas that are conducive to algae

growth.

Trapping — Condensate trapping is a necessity on every

water source heat pump unit. A trap is provided to prevent

the backflow of moisture from the condensate pan and into

the fan intake or downstream into the mechanical system.

The water seal or the length of the trap depends on the

positive or negative pressure on the drain pan. As a rule of

thumb, size the water seal 1 in. for every 1 in. of negative

pressure on the unit. The water seal is the distance from

the bottom of the unit condensate piping connection to

the bottom of the condensate drain line run-out piping.

Therefore, the trap size should be double the water seal

dimension.

Horizontal units — Horizontal units should be sloped to-

ward the drain at a

1

/

4

in. per foot pitch. If it is not possible

to meet the pitch requirement, a condensate pump should

be designed and installed at the unit to pump condensate

to a building drain. Horizontal units are not internally

trapped; therefore an external trap is necessary. Each unit

must be installed with its own individual trap and means to

flush or blow out the condensate drain. It is not acceptable

to use a common trap or vent for multiple units. The con-

densate piping system should not be designed with a pipe

size smaller than the drain connection pipe size.

Vertical units — Vertical units use a condensate hose in-

side the cabinet that acts as a trapping loop, making an ex-

ternal trap unnecessary. Install each unit with its own vent

and means to flush or blow out the condensate drain lines.

Do not install a common trap or vent on vertical units.

Water conditioning

In some applications, maintaining proper water quality

may require higher corrosion protection for the water-to-

refrigerant heat exchanger. Water quality varies from loca-

tion to location and is unique for each job. Water charac-

teristics such as pH value, alkalinity, hardness, and specific

conductance are important when considering any WSHP

application. Water typically includes impurities and hard-

ness that must be removed. The required treatment will de-

pend on the water quality as well as type of system. Water

problems fall into three main categories:

1. Scale formation caused by hard water reduces the

heat transfer rate and increases the water pressure

drop through the heat exchanger. As water is heated,

minerals and salts are precipitated from a solution

and deposited on the inside surface of the pipe or

tube.

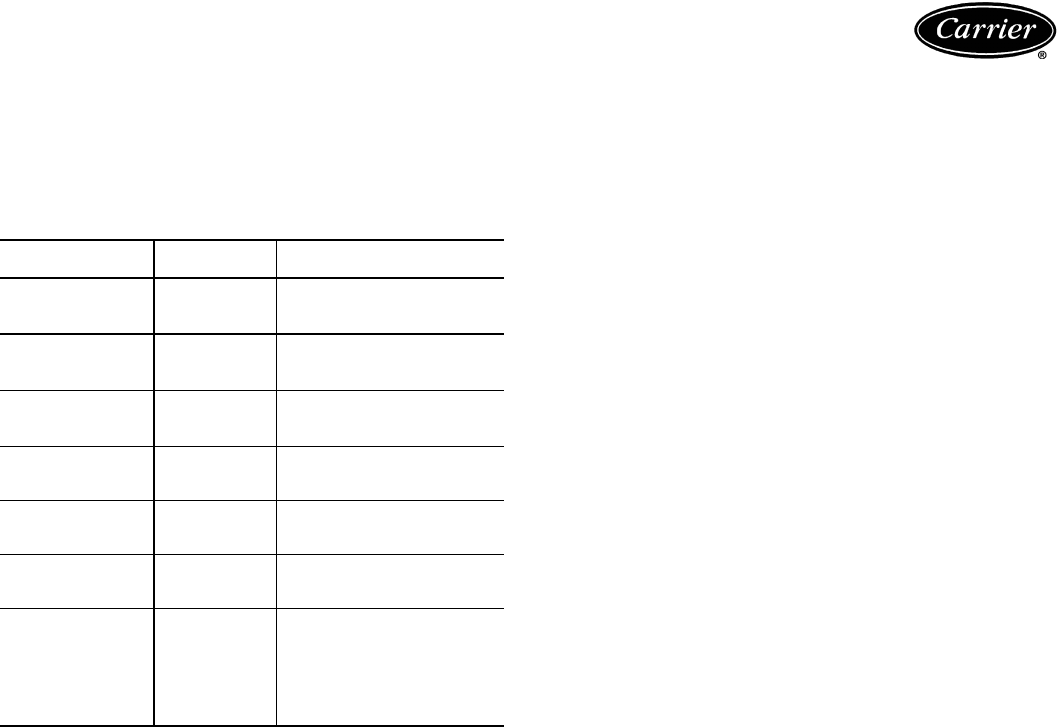

50 SERIES

TYPE

SIZE (tons)

APPLICATION

50RHC,RVC

Horizontal/Vertical

Standard

Efficiency

1

/

2

-5

Efficient, compact, low cost

alternative for retrofit or new

boiler/tower systems.

50RHR,RVR

Horizontal/Vertical

High

Efficiency

1

/

2

-5

Efficient, adaptable unit for

new boiler/tower, ground

water, or ground loop systems.

50RHS,RVS

Horizontal/Vertical

Premium

Efficiency

1

1

/

4

-6

Premium, ultra efficient unit for

new boiler/tower, ground

water, or ground loop systems

50HQ,VQ

Horizontal/Vertical

Large Capacity

6

1

/

2

-25

Designed to handle large

zoned areas for all

applications.

50KQL Console

1

/

2

-1

1

/

2

Attractive design for finished

interior, under-window

installations.

50RTG Rooftop

3-20

Economical solution for IAQ

problems and tempering

ventilation air.

50RWS Water-to-Water

3-30

Used to pre-heat or cool

air and can be used as a

stand-alone or supplemental

boiler/chiller in most hydronic

heating applications. Also

conditions process fluids,

lubricants and refrigerants.

Application data

- Features/Benefits 1

- Table of contents 2

- Features/Benefits (cont) 3

- Model number nomenclature 4

- ARI/ISO capacity ratings 5

- Physical data 6

- Options and accessories 7

- CARRIER AQUAZONE THERMOSTATS 8

- Dimensions 10

- VERTICAL DIMENSIONAL DATA 11

- Performance data 14

- Performance data (cont) 16

- AIRFLOW CORRECTION TABLE 25

- Electrical data 29

- Typical piping and wiring 30

- Typial wiring schematics 31

- Typical control wiring 33

- Application data 34

- Acoustical design 35

- WSHP sound control 35

- Horizontal units 35

- Application data (cont) 36

- Guide specifications 38

- Guide specifications (cont) 40

(20 pages)

(20 pages)

Comments to this Manuals