Carrier AQUAZONE 50RHC006-060 User Manual Page 35

- Page / 44

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

35

2. Corrosion is caused by absorption of gases from the

air coupled with water on exposed metal. Corrosion

is also common in salt-water areas.

3. Organic growths such as algae can reduce the heat

transfer rate by forming an insulating coating on the

inside tube surface. Algae can also promote corrosion

by pitting.

NOTE: In most commercial water loop applications, Aqua-

zone™ WSHP units use copper water-to-refrigerant heat

exchanger. Units can also be equipped with a Cupronickel

heat exchanger for applications where water is outside the

standard contaminant limits for a copper heat exchanger.

WATER QUALITY GUIDELINES

*If the concentration of these corrosives exceeds the maximum allowable

level, then the potential for serious corrosion problems exists.

†Sulfides in the water quickly oxidize when exposed to air, requiring that no

agitation occur as the sample is taken. Unless tested immediately at the

site, the sample will require stabilization with a few drops of one Molar zinc

acetate solution, allowing accurate sulfide determination up to 24 hours

after sampling. A low pH and high alkalinity cause system problems, even

when both values are within ranges shown. The term pH refers to the acid-

ity, basicity, or neutrality of the water supply. Below 7.0, the water is consid-

ered to be acidic. Above 7.0, water is considered to be basic. Neutral water

contains a pH of 7.0.

NOTE: To convert ppm to grains per gallon, divide by 17. Hardness in mg/l is

equivalent to ppm.

Acoustical design

Sound power levels represent the sound produced by the

source, the WSHP unit, with no regard to attenuation be-

tween the source and the space. Acoustical design goals

are necessary to provide criteria for occupied spaces.

These goals help ensure that people are comfortable and

can communicate effectively over the air conditioning sys-

tem and other background noise sources.

Acoustical design goals are desirable sound pressure lev-

els within a given conditioned space and are represented

by Noise Criteria (NC) curves. Noise Criteria (NC) curve

levels represent a peak over a full spectrum of frequencies.

A high value in a low frequency band has the same effect

on NC level as a lower value in a high frequency band. It is

important that sound levels be balanced over the entire

spectrum relative to the NC curve. The lower the NC crite-

ria curve, the more stringent the room acoustical design

must be to meet the design goals.

It is important to know how to convert the unit ratings

from sound power (Lw) to sound pressure (Lp). This

conversion depends on the specifics of the installation’s

acoustic environment.

Assessing an area’s acoustical design means comparing

the sound pressure (Lp) with the NC curve for the selected

area.

Some of the factors that affect conversion of sound

power to sound pressure and consequent NC level include:

• Type of acoustical ceiling

• Use of metal or flex duct

• Absorption in the occupied space

• Location in the occupied space

• Open or closed layout plan

• Use of open or ducted returns

• Orientation of unit to occupant

• Use of lined or unlined duct

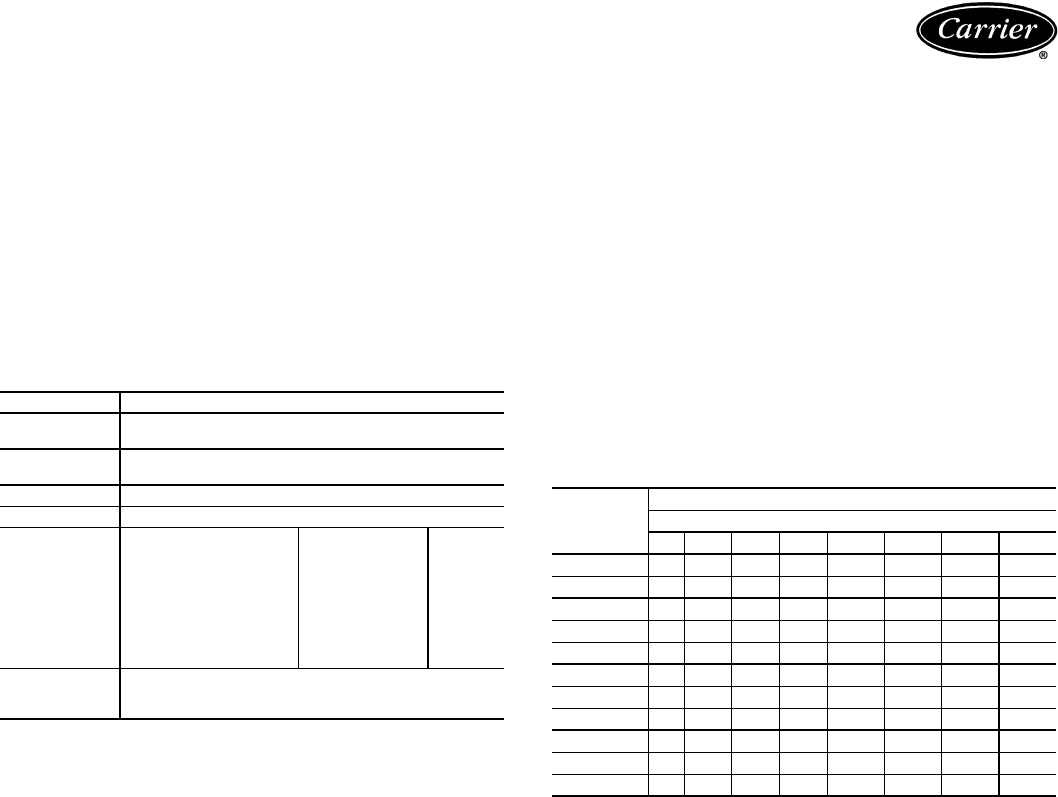

OCTAVE BAND SOUND PRESSURE LEVEL (Lp)

ASSOCIATED WITH NC CURVES

WSHP sound control

Analyzing the projected sound level in the conditioned

space caused by a WSHP unit located in a ceiling plenum is

quite involved. The key is to have good sound power

ratings (Lw) in dB on the equipment to determine the

sound attenuation effect of the ductwork, ceiling and room.

Aquazone equipment includes standard attenuating fea-

tures and offers an advanced mute package. In addition,

Carrier provides suggestions for unit sound design around

the WSHP.

Horizontal units

Use the following guidelines for layout of Aquazone hori-

zontal units to minimize noise:

1. To select quietest equipment, obtain sound power

ratings in accordance with latest standards from

manufacturers.

2. Do not locate units over a space with a required NC

of 40 or less. Instead, locate units above less sensitive

noise areas such as above or in equipment rooms,

utility closets, restrooms, storage rooms, or above

corridors.

3. Provide at least 10 feet between WSHP units to avoid

the additive effect of two noise sources.

CONDITION ACCEPTABLE LEVEL

pH 7 to 9 range for copper. Cupronickel may be used

inthe5to9range.

Total Hardness

Calcium and magnesium carbonate should not

exceed 20 grains per gallon (350 ppm).

Iron Oxides Less than 1 ppm.

Iron Bacteria No level allowable.

Corrosion* Max Allowable

Level

Coaxial

Metal

Ammonia,

Ammonium Hydroxide

0.5 ppm Cu

Ammonium Chloride,

Ammonium Nitrate

0.5 ppm Cu

Ammonium Sulfate 0.5 ppm Cu

Chlorine/Chlorides 0.5 ppm CuNi

Hydrogen Sulfide† None Allowable —

Brackish Use Cupronickel heat exchanger when concentrations

of calcium or sodium chloride are greater than 125 ppm

are present. (Seawater is approximately 25,000 ppm.)

NOISE

CRITERIA

CURVES

OCTAVE BAND SOUND PRESSURE LEVEL (Lp)

Frequency (Hz)

63 125 250 500 1000 2000 4000 8000

NC-15 49 36 26 17 17 14 12 11

NC-20 52 41 33 27 22 19 17 16

NC-25 54 45 38 31 27 24 22 21

NC-30 58 49 41 36 31 29 28 27

NC-35 61 53 45 40 36 34 33 32

NC-40 64 57 50 45 41 39 38 37

NC-45 67 61 54 49 46 44 43 42

NC-50 71 64 58 54 51 49 48 47

NC-55 74 68 63 58 56 54 53 52

NC-60 77 71 67 63 61 59 58 57

NC-65 80 75 71 68 66 64 63 62

- Features/Benefits 1

- Table of contents 2

- Features/Benefits (cont) 3

- Model number nomenclature 4

- ARI/ISO capacity ratings 5

- Physical data 6

- Options and accessories 7

- CARRIER AQUAZONE THERMOSTATS 8

- Dimensions 10

- VERTICAL DIMENSIONAL DATA 11

- Performance data 14

- Performance data (cont) 16

- AIRFLOW CORRECTION TABLE 25

- Electrical data 29

- Typical piping and wiring 30

- Typial wiring schematics 31

- Typical control wiring 33

- Application data 34

- Acoustical design 35

- WSHP sound control 35

- Horizontal units 35

- Application data (cont) 36

- Guide specifications 38

- Guide specifications (cont) 40

(20 pages)

(20 pages)

Comments to this Manuals