Carrier Supra 650 Service Manual Page 20

- Page / 92

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

1--7

62--10828

1

L

B--

B+

2

3

4

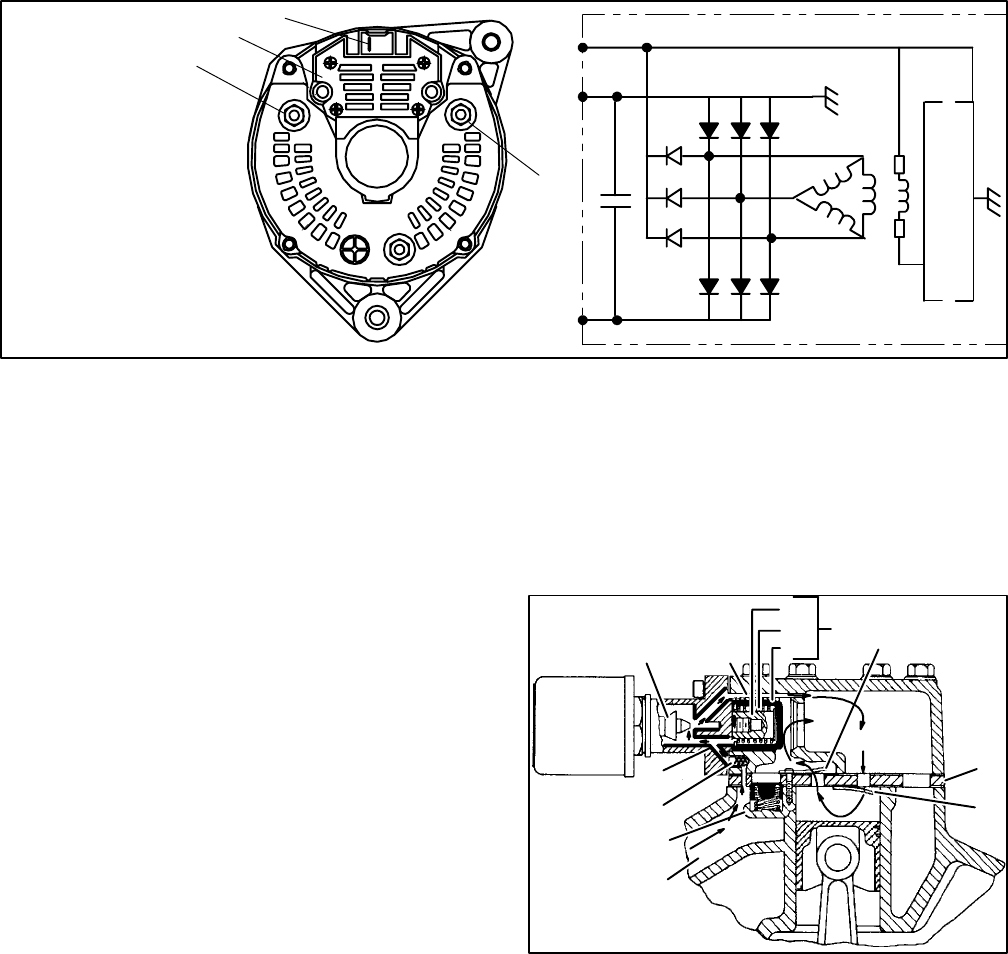

1. Positive Output

Terminal

2. Regulator

3. 12vdc Test Lamp

Terminal

4. Ground Terminal

Figure 1-6. 70 Amp Alternator (P/N 30-60050-04)

1.3.2 Condensing Section Refrigeration System

The condensing section mounted refrigeration system

equipment includes the compressor, condenser/sub-

cooler, accumulator, defrost air switch, filter drier, re-

ceiver, hot gas (three way) valve, hot gas bypass valve

(except for 950) and compressor pressure regulating

valve.

a. Compressor

The compressor assembly includes the refrigerant com-

pressor, suction and discharge service valves, high

pressure switch, unloader(s) (850 and 950 only) and the

suction pressure transducer. The compressor draws

refrigerant gas from the evaporator and delivers it to the

condenser at an increased pressure. The pressure is

such that refrigerant heat can be absorbed by the sur-

rounding air at ordinary temperatures.

b. Compressor Unloader (850 and 950 Only) (Refer

to Section 3.1.7 for detailed information on unloader

temperature control)

The Supra 850 and 950 unit compressors are fitted with

one electric unloader valve. The capacity controlled cyl-

inder is easily identified by the solenoid which extends

from the side of the cylinder head. When the solenoid is

energized two cylinders are unloaded. The unloaded

cylinders operate with little or no pressure differential,

consuming very little power. A description of unloader

operation is provided in the following steps.

Unloaded Operation

Pressure from the discharge manifold (Figure 1-7, item

15) passes through the strainer (9) and bleed orifice (8)

to the back of the piston bypass valve (7). Unless bled

away, this pressure would tend to close the piston (6)

against the piston spring (5) pressure.

With the solenoid valve (1) energized the solenoid valve

stem (2) will open the gas bypass port (3).

Refrigerant pressure will be bled to the suction manifold

(10) through the opened gas bypass port . A reduction in

pressure on the piston bypass valve will take place be-

cause the rate of bleed through the gas bypass port is

greater than the rate of bleed through the bleed orifice

(8).

When the pressure behind the piston has been reduced

sufficiently, the valve spring will force the piston bypass

valve back, opening the gas bypass from the discharge

manifold to the suction manifold.

Discharge pressure in the discharge manifold will close

the discharge piston check valve assembly (14) isolat-

ing the compressor discharge manifold from the individ-

ual cylinder bank manifold.

The unloaded cylinder bank will continue to operate fully

unloaded until the solenoid valve control device is de--

energized and the gas bypass port is closed.

10

11

12

13

4

6

5

15

14

1

9

2

3

8

7

1. Solenoid

V

alve

2. Valve Stem

3. Gas Bypass Port

4. Spring Guide

5. Spring

6. Piston

7. Piston Bypass Valve

8. Bleed Orifice

9. Strainer

10.Suction Manifold

11. Cylinder Discharge

Valve

12. Valve Plate

13. Cylinder Suction

Valve

14. Discharge Piston

Check Valve

Assembly

15. Discharge Manifold

Figure 1-7. Cylinder Head -- Unloaded

- OPERATION & SERVICE 1

- OPERATION AND 2

- SERVICE MANUAL 2

- TABLE OF CONTENTS 3

- LIST OF ILLUSTRATIONS 8

- LIST OF TABLES 9

- SAFETY SUMMARY 10

- SECTION 1 14

- DESCRIPTION 14

- 20 35° F 15

- -20 35° F 32

- SECTION 3 43

- SUPRA 550/650/750/850 50

- CONTINUOUS MODE 50

- START / STOP MODE 51

- SUPRA 950 52

- SECTION 4 54

- 62--10828 75

- Table 4-4 Configuration Table 75

- 62--108284--23 76

- SECTION 5 79

- TROUBLESHOOTING 79

- SECTION 6 85

- CONNECT TO OVERLOAD RELAY 87

(29 pages)

(29 pages)

Soy mecánico mantenedor. Necesito manuales técnicos